Our Expertise

Precision Manufacturing for Demanding Industries

At MechCraft, we combine cutting-edge technology with engineering excellence to deliver high-performance mechanical components tailored to your exact specifications.

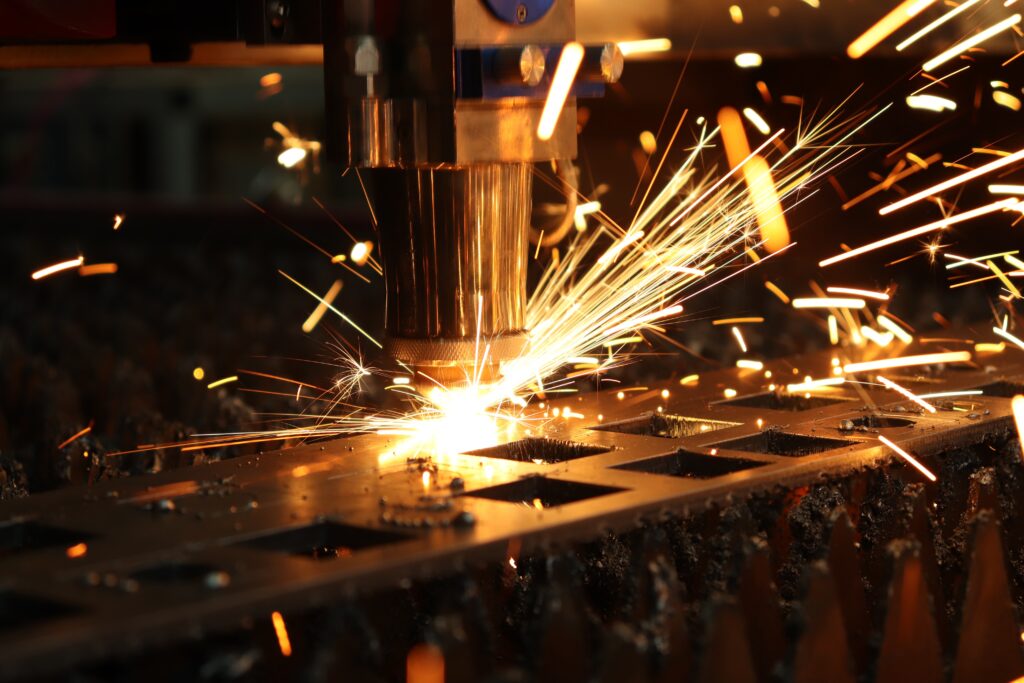

CNC Laser Cutting

At MechCraft, our advanced CNC laser cutting technology delivers complex sheet metal parts with micron-level accuracy, ensuring tight tolerances (±0.05mm) for even the most demanding applications. We achieve superior surface finishes that enhance performance and durability, making our components ideal for aerospace, automotive, and industrial machinery. Additionally, our TubeCut system specializes in high-precision 3D pipe cutting, enabling intricate designs and perfect fitment for structural and fluid systems. Whether you need flat sheet metal components or complex tubular structures, our laser cutting solutions combine speed, precision, and reliability to meet your toughest manufacturing challenges.

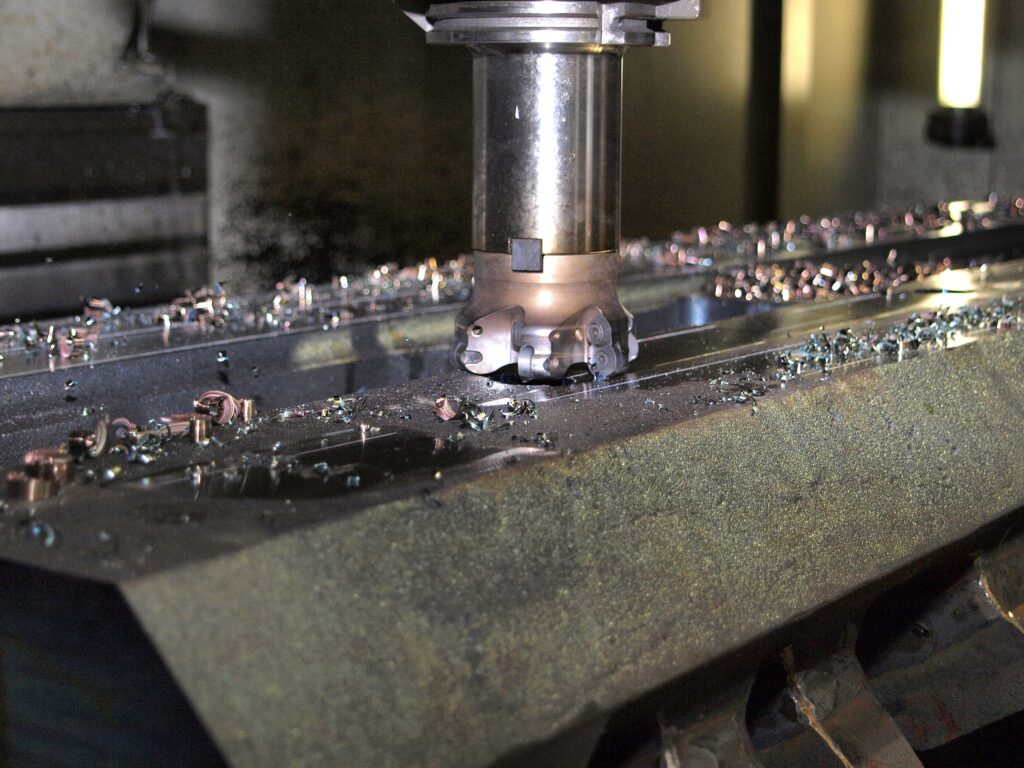

Vertical Machining Centre for High-Precision 3D Components

MechCraft’s Vertical Machining Centres (VMCs) deliver exceptional precision for complex 3D parts, achieving micron-level accuracy to meet the most demanding specifications. With tight tolerances of ±0.005mm, our VMCs are engineered for critical applications in aerospace, medical devices, and high-performance machinery. Advanced automation ensures unmatched repeatability, while high-speed spindles and rigid construction maximize efficiency and productivity. Whether prototyping or full-scale production, our VMC solutions guarantee flawless accuracy, consistency, and speed—empowering your business with reliable, high-quality machined components.

Precision Laser Welding for Flawless Joining Solutions

MechCraft’s laser welding technology delivers micron-precise, high-strength welds for critical applications across aerospace, medical devices, and precision engineering. Our advanced systems produce clean, spatter-free seams with minimal heat distortion, preserving material integrity in even the most delicate components.

Key Advantages:

- Sub-millimeter accuracyfor hermetic seals and intricate joints

- Automated repeatability(±0.01mm consistency) for high-volume production

- Multi-material capability(stainless steels, titanium, aluminum alloys)

- Non-contact processreduces part stress vs traditional welding

From ultra-thin medical instruments to high-stress aerospace assemblies, our laser welding solutions combine NDT-certified quality with industry-leading throughput.

Advanced Argon Welding for Superior Metal Joining

At MechCraft, our argon welding (TIG/GTAW) services deliver clean, high-purity welds for critical applications where precision and strength matter most. Utilizing 99.996% pure argon shielding gas, we produce oxidization-free joints with exceptional structural integrity across aerospace, nuclear, and high-value fabrication projects.

Why Choose Our Argon Welding?

- Aerospace-grade precisionwith X-ray/UT-certified weld quality

- Reactive metal expertise(titanium, inconel, magnesium alloys)

- Zero porosity seamsfor pressure vessels and cryogenic systems

- Thin-to-thick capability(0.1mm to 25mm single-pass welds)

Our ASME & ISO 9606-certified welders combine pulsed-arc technology with orbital automation for repeatable perfection in:

Ø Exotic alloy piping

Ø Semiconductor chamber fabrication

Ø Medical implant assemblies

Precision 3D Printing for Advanced Manufacturing

At MechCraft, we harness the latest industrial-grade 3D printing technologies to transform your designs into high-performance functional parts. Our additive manufacturing solutions deliver rapid prototyping, low-volume production, and complex geometries with unmatched accuracy and material versatility.

Why Choose Our 3D Printing Services?

Quality Guaranteed – Every part undergoes dimensional inspection and material testing to ensure it meets your exact specifications.